Rotating

At Pumps and Mechanical equipment BU, through our world – renowned principals, we provide end-to-end industrial product solutions across industrial sectors like Oil & Gas, Chemical & Petrochemical, Power, Food & Beverages, Water & Wastewater..

Product and Services

We offer custom engineered, expertly built metering pumps and packages.The product range includes a complete program of both packed plunger and sealless hydraulically actuated.

Diaphragm pumps, with a total performance range covering flows up to 180 m3/h and pressures up to 1,200 bar

Features of LEWA diaphragm pumps includes:-

Complies to API 675

Complies to API 675 Totally leak-tight, with secondary containment by special “sandwich” diaphragm.

Totally leak-tight, with secondary containment by special “sandwich” diaphragm. Diaphragm condition monitor and built-in hydraulic pressure relief for safety.

Diaphragm condition monitor and built-in hydraulic pressure relief for safety. High suction pressure capability, even with difficult-to-handle liquids such as aggressives, slurries, low lubricity, low viscosity, toxic, flammable, etc..

High suction pressure capability, even with difficult-to-handle liquids such as aggressives, slurries, low lubricity, low viscosity, toxic, flammable, etc..

For Queries

info@powerlinesolutions.com

We promote FINISH THOMPSON INC (FTI), the best plastic mag drive pump manufacturer in the market.

Features of FTI mag drive pump includes:-

Neodymium magnetic drive system.

Neodymium magnetic drive system. High dry run capability.

High dry run capability. Best suitable for highly corrosive medium.

Best suitable for highly corrosive medium. Flows up to 50 m3/hr @ 61.3 meters head.

Flows up to 50 m3/hr @ 61.3 meters head.

FTI also produce Sealless self -priming pumps allowing it to lift fluid from as deep as 7.6 meters

FTI drum pumps are well-known for its quality. Featuring multiple material options and connections, they are best suitable for multiple applications.

FTI is also well known for its ANSI dimensional ETFE lined pumps

For Queries

info@powerlinesolutions.com

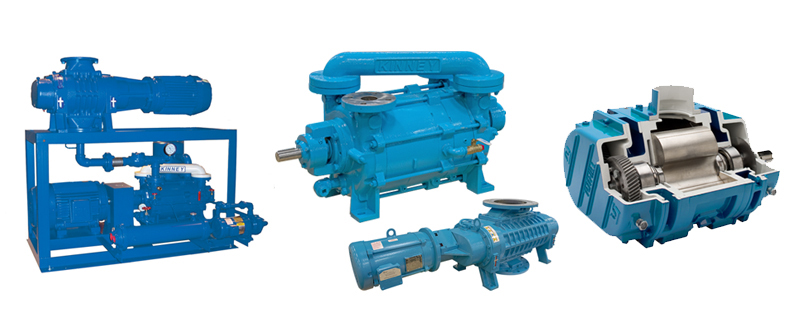

Our product range covers Liquid Ring, Rotary Piston, Rotary Vane and Dry Screw vacuum pumps capable of producing a very low vacuum at a higher pumping speed, serving a wide range of markets and applications.

Our product range covers Liquid Ring, Rotary Piston, Rotary Vane and Dry Screw vacuum pumps capable of producing a very low vacuum at a higher pumping speed, serving a wide range of markets and applications. Engineered vacuum systems including Pump/Booster skids are also available.

Engineered vacuum systems including Pump/Booster skids are also available. We size a wide range of rotary lobe blowers and vacuum boosters into applications spanning several markets. Custom engineered blower package are available to meet the unique specifications of your application.

We size a wide range of rotary lobe blowers and vacuum boosters into applications spanning several markets. Custom engineered blower package are available to meet the unique specifications of your application.

For Queries

info@powerlinesolutions.com

For more than 90 years, COPPUS portable ventilators and cooling products have been recognized as leaders in providing reliable, ventilation to meet the demands of safety and maintenance personnel around the world in refineries, chemical plants, steel mills….etc.

Products include :-

Compressed air driven confined space ventilators &air movers.

Compressed air driven confined space ventilators &air movers. Electrical driven Centrifugal & vane axial blowers / exhausters

Electrical driven Centrifugal & vane axial blowers / exhausters Product & personnel cooling fans

Product & personnel cooling fans

For Queries

info@powerlinesolutions.com

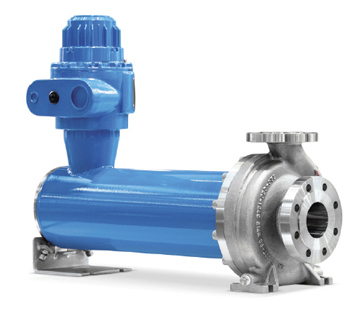

NIKKISO, a pioneer in “Canned Motor Pumps”, delivers sealless pumps where zero leakage is obligatory.

Flow range covers up to 780 m3/h and head up to 210 metes

Flow range covers up to 780 m3/h and head up to 210 metes A wide range of liquid end materials are available which enable to suit your unique application

A wide range of liquid end materials are available which enable to suit your unique application Pumps complying to ASME B73.3 & API 685 standards are available

Pumps complying to ASME B73.3 & API 685 standards are available Capable of delivering pumps suitable for Cryogenic applications

Capable of delivering pumps suitable for Cryogenic applications

For Queries

info@powerlinesolutions.com

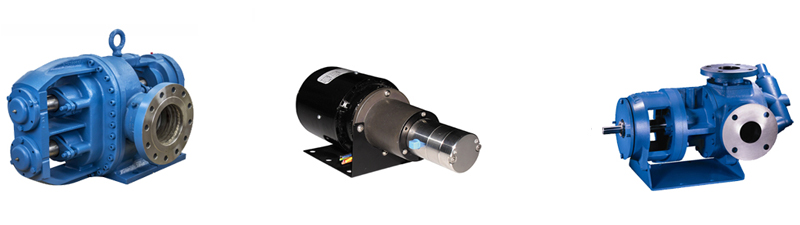

Capable of supplying a wide spectrum of applications, from a non-pulsing magnetically driven external gear pump, to the more robust internal gear pumps and heavy duty circumferential pumps (capable of handling up to 20 million SSU).

Applications Includes :-

Loading & Unloading of fuel oil

Loading & Unloading of fuel oil Asphalt

Asphalt Chemical processing

Chemical processing Transferring of high viscous fluids

Transferring of high viscous fluids Chemical dosing

Chemical dosing Lubrication application

Lubrication application Pumps complying to API 674 & 676

Pumps complying to API 674 & 676

For Queries

info@powerlinesolutions.com

Salvatore Robuschi Pump

Salvatore Robuschi's Centrifugal Pumps can be used in many industrial fields. chemical and pharmaceutical industry (preparation of active ingredients), food industry (washing of fruits and vegetables, vacuum conveying and co-centration), distillation, purification, tanning, textiles and in all those sectors that present pumping issues suspended solids, products difficult to convey. vacuum solution. Centrifugal Pumps built according to ISO 5199/ ISO 2858 norms.

Process Pumps

Process Pumps Vertical, Cantilever Pumps

Vertical, Cantilever Pumps Close Coupled Pumps

Close Coupled Pumps Water Pumps

Water Pumps

We proudly represent Klaus Union – Germany, a renowned name in seal-less mag drive centrifugal pump technology.

The product range includes :-

Mag drive pumps complying to ASME B73.3 & API 685 standards

Mag drive pumps complying to ASME B73.3 & API 685 standards Submerged Vertical Seal-less mag drive pumps

Submerged Vertical Seal-less mag drive pumps

Features

Tailor made solutions to your applications

Tailor made solutions to your applications Special features to handle liquid containing solid particles

Special features to handle liquid containing solid particles Flow range covers up to 3500 m3/h and head up to 700 metes

Flow range covers up to 3500 m3/h and head up to 700 metes Wide range of material selection available for wetted parts

Wide range of material selection available for wetted parts

For Queries

info@powerlinesolutions.com

Twin Screw Pumps from Klaus Union are mechanically sealed Single/Double volute, self-priming positive displacement pumps for low, medium and high-pressure duty. It is suitable for a wide range of applications and can handle corrosive, non-lubricating as well as high viscosity liquids like Crude Oil and finished products, Fuel oil, Tar, Bitumen ….etc

Pumps complies with API 676 standard.

Double volute twin screw pumps covers an operating range of :-

Mag drive pumps complying to ASME B73.3 & API 685 standards

Mag drive pumps complying to ASME B73.3 & API 685 standards Submerged Vertical Seal-less mag drive pumps

Submerged Vertical Seal-less mag drive pumps

Single volute twin screw pumps covers an operating range of: -

Flow up to 1800 m3/hr @ 40 Bar

Flow up to 1800 m3/hr @ 40 Bar Temperature Range: -120°C to +350 °C

Temperature Range: -120°C to +350 °C Viscosities up to 100,000 cSt

Viscosities up to 100,000 cSt

Single volute twin screw pumps can also be manufactured with mag drive instead of mechanically sealed option.

For Queries

info@powerlinesolutions.com

From the global leader in AODD pumps, Wilden – USA, we offer :-

Air Operated Double Diaphragm Pumps.

Air Operated Double Diaphragm Pumps. Variety of Air Distribution Systems & Accessories.

Variety of Air Distribution Systems & Accessories.

Features :-

Flow Rates up to 1048 LPM & Discharge pressure up to 17.2 Bar

Flow Rates up to 1048 LPM & Discharge pressure up to 17.2 Bar Low Air Consumption with ProFlo-SHIFT Technology, up to 60% more efficient.

Low Air Consumption with ProFlo-SHIFT Technology, up to 60% more efficient. Available in SS, Polypropylene, Aluminum, Haste Alloy

Available in SS, Polypropylene, Aluminum, Haste Alloy Diaphragms in Teflon, Neoprene, Wilflex, EPDM & Chem-Fuse

Diaphragms in Teflon, Neoprene, Wilflex, EPDM & Chem-Fuse

Almatec® is a premier manufacturer of air-operated double-diaphragm (AODD) pumps and respected leader worldwide due to superior product quality and unmatched German innovation.

Solid body construction of the plastic pumps with high safety level due to the ring-tightening structure.

Solid body construction of the plastic pumps with high safety level due to the ring-tightening structure. Material selection with required corrosive and abrasion resistance for pump housings and internals.

Material selection with required corrosive and abrasion resistance for pump housings and internals. Conductive models for explosion-proof areas and flammable liquids (ATEX conformity)

Conductive models for explosion-proof areas and flammable liquids (ATEX conformity) Non-Stalling PERSWING Air Valve, No Metal at all (PETP Material).

Non-Stalling PERSWING Air Valve, No Metal at all (PETP Material). Sizes ¼” to 3”.

Sizes ¼” to 3”. Single piece Diaphragms with Integrated Metal Core, available in PTFE, EPDM & NBR.

Single piece Diaphragms with Integrated Metal Core, available in PTFE, EPDM & NBR. Low Noise Levels.

Low Noise Levels.

For Queries

info@powerlinesolutions.comAfter Sales Support

We have a well-equipped workshop in Saudi Arabia.

We offer an on-site service as well as an in-house service when it comes to repairing or the retrofitting of rotating and static equipment.

Our highly trained engineer/technicians will also do on-site fault-finding and report writing.

Powerline can also offer you the client technical advice in the selection of the pumps, valves, heat exchangers, condensers, vacuum packages, and blowers needed for your process.

We will also assist with the installation process and the commissioning and startup of any new installations.

Scope of works for service and repairs.

Disconnect the pump from the pipework and drive coupling or the Pump can be collected at the customer site.

Disconnect the pump from the pipework and drive coupling or the Pump can be collected at the customer site. The pump is carefully disassembled, and all critical clearances and dimensions are recorded. Our engineer will inspect all the pump parts.

The pump is carefully disassembled, and all critical clearances and dimensions are recorded. Our engineer will inspect all the pump parts. Upon completion of the inspection, Powerline will submit a pump report with a detailed scope of work for the repairs as well as a firm quotation for the costs associated with the pump repair.

Upon completion of the inspection, Powerline will submit a pump report with a detailed scope of work for the repairs as well as a firm quotation for the costs associated with the pump repair. Feedback to the client will be submitted via E-mail.

Feedback to the client will be submitted via E-mail. After receipt of the order, all components are then prepared for bead blasting and cleaning, the repair begins and all components requiring repairs are meticulously replaced or reverse-engineered to the necessary tolerances.

After receipt of the order, all components are then prepared for bead blasting and cleaning, the repair begins and all components requiring repairs are meticulously replaced or reverse-engineered to the necessary tolerances. Mechanical seal will be tested on our test rig before being installed back on the pump shaft.

Mechanical seal will be tested on our test rig before being installed back on the pump shaft. The pump will be re-assembled back to the original equipment manufacturer’s specifications and resprayed.

The pump will be re-assembled back to the original equipment manufacturer’s specifications and resprayed. Pump and mechanical seal are tested for any leaks.

Pump and mechanical seal are tested for any leaks. Pump is delivered to the client.

Pump is delivered to the client.

For Queries

info@powerlinesolutions.com

Vertical Turbine Pumps

The Trillium Flow Technologies™ Floway® brand is an international industry leader with more than 80 years of proven experience providing vertical turbine pumps to the water and wastewater, oil and gas, mining, energy, and industrial markets.

Floway® pumps are known around the world for their superior quality, reliable hydraulic performance, and long service life.

Our vertical turbine pumps are available in a wide range of sizes and stages that allow this pump to meet NPSH requirements.

Features of Floway Pumps:-

VFP Vertical Turbine Fire Protection Pump

VFP Vertical Turbine Fire Protection Pump VHP API 610 Vertical Turbine Pump

VHP API 610 Vertical Turbine Pump VSB Submersible Vertical Turbine Pump

VSB Submersible Vertical Turbine Pump VTP General Vertical Turbine Pump

VTP General Vertical Turbine Pump VTSP Vertical Turbine Solids Pump

VTSP Vertical Turbine Solids Pump

ROTO-JET®

The Roto-Jet® brand encompasses high-pressure, single-stage centrifugal pumps with advanced pitot tube technology that are successful for demanding low-flow, high-head applications.

Roto-Jet® is built on the pitot tube pump concept which, because of its unique rotating case design, is sometimes referred to as “the backward pump”. Over the decades, the pitot tube’s simple design and versatile performance have achieved a reputation as the solution to many high-pressure pumping problems.

Features of Floway Pumps:-

No external lube system required

No external lube system required No wear rings or close running clearances

No wear rings or close running clearances Robust design is insensitive to process upsets

Robust design is insensitive to process upsets Pulsation free flow over the entire head-flow curve

Pulsation free flow over the entire head-flow curve Reduced life cycle cost by optimizing hydraulic efficiency

Reduced life cycle cost by optimizing hydraulic efficiency Process seals exposed only to suction pressure for maximum seal life

Process seals exposed only to suction pressure for maximum seal life High heads achieved in a single stage at low operating speeds compared to other low-flow, high-head pumps

High heads achieved in a single stage at low operating speeds compared to other low-flow, high-head pumps

WEMCO®

Founded as Western Equipment Manufacturing (WEMCO) and originally focused on the mining industry, WEMCO® originated a process called mechanical flotation for the removal of fine solids particles for clarification of mining wastewater and the collection and recovery of valuable minerals such as gold and silver.

WEMCO® pumps and equipment are designed to be robust, reliable, and safe. We have more than 50 years of experience serving municipal and industrial customers in markets as diverse as water and wastewater, agri-food, solid bulk and sand applications, chemicals, and general industry.

Types :-

1. WEMCO® Hydrogritter® Grit Removal System

1. WEMCO® Hydrogritter® Grit Removal System 2. WEMCO® Torque-Flow® Recessed Impeller Pump

2. WEMCO® Torque-Flow® Recessed Impeller Pump

WSP™

The Trillium Flow Technologies™ WSP™ self-primer pump is a rugged and dependable self-priming, solids handling trash pump. Our focus is on simplifying maintenance and reducing life cycle costs for our customers through innovative design and durability.

The Trillium Flow Technologies™ WSP™ self-primer pump is a rugged and dependable self-priming, solids handling trash pump. Distinguishable from our competitors, the WSP™ self-primer pump design allows for a shim-less, tool-less impeller adjustment and ease of suction flap valve replacement.

Using advanced engineering techniques, we have developed the WSP™ range of pumps to serve food and beverage processing, waste management, and material processing industries, globally. Our focus is on simplifying maintenance and reducing life cycle costs for our customers through innovative design and durability.

Types :-

1. WSP™ CHOP FLOW PUMP

1. WSP™ CHOP FLOW PUMP 2. WSP™ FOOD TRANSFER PUMP

2. WSP™ FOOD TRANSFER PUMP 3. WSP™ NON-CLOG PUMP

3. WSP™ NON-CLOG PUMP 4. WSP™ SELF-PRIMER PUMP

4. WSP™ SELF-PRIMER PUMP

Torquing Tools

New World Technologies Inc. is a leading Canadian manufacturer of pneumatic, battery-powered, and electronic pistol grip torque wrenches which are marketed under the RAD trademark.

Types :-

The B-RAD Select battery series torque wrenches come with two simple buttons to increase or decrease the value by 10 ft/lbs (10 Nm).

The B-RAD Select battery series torque wrenches come with two simple buttons to increase or decrease the value by 10 ft/lbs (10 Nm). RAD electric torque wrenches are lightweight and compact torque wrenches suitable for heavy industrial use.

RAD electric torque wrenches are lightweight and compact torque wrenches suitable for heavy industrial use. RAD planetary gear torque wrenches are vibration-free and have the accuracy to prevent accidentally under - and over-tightening.

RAD planetary gear torque wrenches are vibration-free and have the accuracy to prevent accidentally under - and over-tightening.

Steam Turbines

We offer a comprehensive range of steam turbines up to 24 MW. These innovative and economical machines have a simple modular design that enables performance optimization in a variety of applications. Offering a series of fully compatible models, we can achieve optimal configuration and match your needs as accurately as possible.

Howden Kühnle, Kopp & Kausch (KK&K) to meet the needs of ecological power generation

Best solution for waste and biomass incineration, heat recovery, mechanical drives, and much more. Our steam turbines meet customer requirements for economic installation and operation and provide excellent flexibility for complex industrial processes.

Whether you need a generator drive for power generation or a mechanical drive for compressors, blowers, and pumps, just talk to us.

DMW Corporation, Japan

In September 1910. The Company commenced its business with the object of manufacturing water turbines, pumps etc. During its business expansion, fans, blowers, and other machinery works were added to meet engineering requirement under the name of Dengyosha Prime Mover Works, Ltd. In June 1955, the business section of water turbine and the industrial machinery section including pumps, fans, blowers, etc. were separated. The former was taken over by Tokyo Shibaura Electric Co., Ltd. (Present name: Toshiba Corporation) and the latter by the present Company under the name of Dengyosha Machine Works, Ltd. On July 1, 1987, the company name short to DMW Corporation as it is.

We offer the following DMW Products in Saudi Arabia

Pumps

Horizontal Single Stage Pumps API 610, Horizontal Multistage Pumps BB3 to API 610

Horizontal Single Stage Pumps API 610, Horizontal Multistage Pumps BB3 to API 610 Horizontal Multistage Pumps BB5 to API 610

Horizontal Multistage Pumps BB5 to API 610 Horizontal Double Suction Pumps BB1 to API610

Horizontal Double Suction Pumps BB1 to API610 Large Vertical VS1 pumps (API610 available)

Large Vertical VS1 pumps (API610 available) Middle Sized Vertical VS1 pumps (API610 available, Lengthy shaft available)

Middle Sized Vertical VS1 pumps (API610 available, Lengthy shaft available) Middle Sized Vertical VS1 or pumps with Suction (Barrel) Tank

Middle Sized Vertical VS1 or pumps with Suction (Barrel) Tank Energy Recovery Device Capacity: 5,000, 10,000, 25,000 m3/day

Energy Recovery Device Capacity: 5,000, 10,000, 25,000 m3/day

Wilo Pump

Wilo is one of the world's leading manufacturers of pumps and pump systems for building services, water management, and groundwater applications.

Wilo SE is a European manufacturer of pumps and pump systems for the building technology, water and industrial sectors with headquarters in Dortmund, Germany. Founded in 1872 as copper and brass factory by Louis Opländer, the company has over 60 subsidiaries in more than 50 countries and employs about 7,800 people worldwide. Wilo produces pumps that guarantee maximum reliability, flexibility and efficiency. Our key services are positioned in the sectors of Water Management, Building Services and Industry.

Using advanced engineering techniques, we have developed the WSP™ range of pumps to serve food and beverage processing, waste management, and material processing industries, globally. Our focus is on simplifying maintenance and reducing life cycle costs for our customers through innovative design and durability.

Types :-

Residential & Commercial Building Services

Residential & Commercial Building Services District Cooling plants

District Cooling plants Water Waste & Sewage treatment

Water Waste & Sewage treatment Irrigation & Pumping Station

Irrigation & Pumping Station

Salvatore Robuschi Pump

Salvatore Robuschi's Centrifugal Pumps can be used in many industrial fields. chemical and pharmaceutical industry (preparation of active ingredients), food industry (washing of fruits and vegetables, vacuum conveying and co-centration), distillation, purification, tanning, textiles and in all those sectors that present pumping issues suspended solids, products difficult to convey. vacuum solution. Centrifugal Pumps built according to ISO 5199/ ISO 2858 norms.

Process Pumps

Process Pumps Vertical, Cantilever Pumps

Vertical, Cantilever Pumps Close Coupled Pumps

Close Coupled Pumps Water Pumps

Water Pumps

DMW Corporation, Japan

In September 1910. The Company commenced its business with the object of manufacturing water turbines, pumps etc. During its business expansion, fans, blowers, and other machinery works were added to meet engineering requirement under the name of Dengyosha Prime Mover Works, Ltd. In June 1955, the business section of water turbine and the industrial machinery section including pumps, fans, blowers, etc. were separated. The former was taken over by Tokyo Shibaura Electric Co., Ltd. (Present name: Toshiba Corporation) and the latter by the present Company under the name of Dengyosha Machine Works, Ltd. On July 1, 1987, the company name short to DMW Corporation as it is.

We offer the following DMW Products in Saudi Arabia

Blowers & Fans

Air Blower for Sulfur Recovery Unit

Air Blower for Sulfur Recovery Unit Multistage Air Blower

Multistage Air Blower Boost Up Fan

Boost Up Fan Forced Draft Fan

Forced Draft Fan Induced Draft (ID) Fan, Gas Recirculation Fan

Induced Draft (ID) Fan, Gas Recirculation Fan

Progressive Cavity Pumps

We promote pumps from PCM, one of the leading manufacturers of Progressive Cavity Pumps and fluid handling system in the world. The typical features of PCM pumps are:

Low life cycle costs

Low life cycle costs

Elastomer expertise through in-house manufacturing

Elastomer expertise through in-house manufacturing

Eco-designed pumps

Eco-designed pumps

PCM offers versatile, robust and easy to maintain technical pumping solutions, designed to adapt to all needs in the Oil& Gas, Food or Industry sectors.

With vast amount of knowledge and experience gained over the years, we can assist you with any Progressive Cavity pump requirement.

Apart from PC Pumps, PCM also manufactures peristaltic pumps which complement their product range very well.

Chopper Pumps, Mixers and Aerators

Powerline Solutions are the authorized distributors of Landia A/S, the pioneers of the chopper pump technology. The range of products Landia offers are

Dry installed Chopper/ sludge Pumps

Dry installed Chopper/ sludge Pumps Submerged Chopper/ sludge pumps

Submerged Chopper/ sludge pumps

Submersible and Side entry Mixers

Submersible and Side entry Mixers

Aerators

Aerators

MBBR mixers

MBBR mixers

Inventors of the technology, Landia chopper pumps are equipped with a special knife system to meet the need for macerating and pumping liquids with high solid content like sludge and thick slurries. Using open impellers and their knife system, Landia pumps ensure problem-free operation under conditions where many other pumps have problems with clogging.

Valves

Thanks to the cooperation with all the most well-known valve manufacturers, Powerline can supply a complete valve package to clients all over the Kingdom of Saudi Arabia, according to customer’s needs.

Product and Services

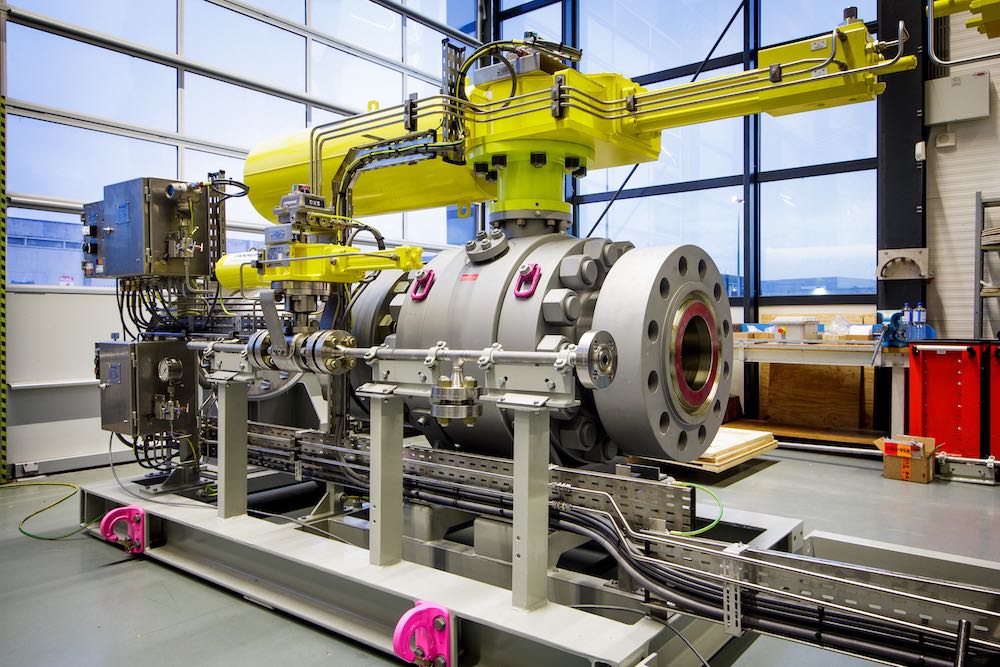

Ball valve

We offer a wide range of ball valves from an array of top-quality ball valve manufacturers. Ball valves from us are durable, reliable, and built to last. Floating, Trunnion, Rising Stem, Dual Piston Effect, Top Entry

Forged and Cast

Forged and Cast Flanged, Threaded, HUB, Socket & Butt-Welded ends.

Flanged, Threaded, HUB, Socket & Butt-Welded ends. Size from 1/4″ to 56″

Size from 1/4″ to 56″ Class from 150 up to 4500

s

Class from 150 up to 4500

s  Soft or metal seated.

Soft or metal seated. Reduced or full bore

Reduced or full bore Fire Safe

Fire Safe Anti Blowout Stem

Anti Blowout Stem Antistatic Device

Antistatic Device Operating temperatures: -196°C – + 788°C

Operating temperatures: -196°C – + 788°C Materials: LTCS, CS, SS, Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Materials: LTCS, CS, SS, Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Butterfly Valves

We are a supplier of Butterfly valves to the oilfield, petrochemical, waste, and water sectors in Saudi Arabia. Our valves are one of the most durable of all resilient-seated butterfly valves in the industry, the butterfly valve excels in a wide variety of applications. Concentric, Double, and Triple Offset

Flanged, Lug, Wafer, HUB, Socket & Butt-Welded ends.

Flanged, Lug, Wafer, HUB, Socket & Butt-Welded ends. Size from 2″ to 112″

Size from 2″ to 112″ Class from 150 up to 4500

Class from 150 up to 4500 Operating temperatures: -196°C – +788°C

Operating temperatures: -196°C – +788°C Materials: LTCS, CS, SS, Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Materials: LTCS, CS, SS, Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Gate Valves

Our Gate Valves are from genuine guaranteed raw material with material test certificates, hydraulic test certificates, and MTC 3.1 available with all supplies. Also, we can provide valves with third-party inspection agencies.

Wedge, Dual Expanding, Parallel Slide, Thru Conduit

Flanged, Threaded, HUB, Socket & Butt-Welded ends.

Flanged, Threaded, HUB, Socket & Butt-Welded ends. Size from 1/4″ to 56″

Size from 1/4″ to 56″ Class from 150 up to 4500

Class from 150 up to 4500 Operating temperatures: -196°C – +788°C

Operating temperatures: -196°C – +788°C Materials: LTCS, CS, SS, Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Materials: LTCS, CS, SS, Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Globe valves

Globe valves are designed to stop, start, and regulate flow within a pipeline, by means of throttling and isolation. These types of valves can be used in application with marine ballast systems, as well as heating and air conditioning, water distribution and/or treatment, and much more.

Flanged, Threaded, HUB, Socket & Butt-Welded ends.

Flanged, Threaded, HUB, Socket & Butt-Welded ends. Size from 1/4″ to 56″

Size from 1/4″ to 56″ Class from 150 up to 4500

Class from 150 up to 4500 Operating temperatures: -196°C – +788°C

Operating temperatures: -196°C – +788°C Materials: LTCS, CS, SS, Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

Materials: LTCS, CS, SS, Exotic Alloys – 6Mo, Hastelloy, Inconel, Duplex etc.

DESIGN AND MANUFACTURING

BS 1873: Steel Globe And Globe Stop And Check Valves (Flanged And Butt- Welding Ends) For The Petroleum, Petrochemical And Allied Industries.

BS 1873: Steel Globe And Globe Stop And Check Valves (Flanged And Butt- Welding Ends) For The Petroleum, Petrochemical And Allied Industries. B 16.34: Valves-Flanged, Threaded, and Welding End.. B5-5352 (replaced by ISO 15761).

B 16.34: Valves-Flanged, Threaded, and Welding End.. B5-5352 (replaced by ISO 15761). ISO 15761: Steel Gate, Globe, and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries (Equivalent to API 602).

ISO 15761: Steel Gate, Globe, and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries (Equivalent to API 602). API 602: Steel Gate, Globe, and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries (Equivalent to ISO 15761).

API 602: Steel Gate, Globe, and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries (Equivalent to ISO 15761).

INSPECTION AND TEST

API: API 598: Valve Inspection and Testing.

API: API 598: Valve Inspection and Testing. BS 1873: Steel Globe and Globe Stop and Check Valves (Flanged and Butt-Welding Ends) For the Petroleum, Petrochemical, and Allied Industries.

BS 1873: Steel Globe and Globe Stop and Check Valves (Flanged and Butt-Welding Ends) For the Petroleum, Petrochemical, and Allied Industries. API: ISO 15848: Industrial Valves - Measurement, test, and qualification procedures for fugitive emissions.

API: ISO 15848: Industrial Valves - Measurement, test, and qualification procedures for fugitive emissions.

FLANGE DIMENSION

ASME B 16.5: Pipe Flanges and Flanged Fittings.

ASME B 16.5: Pipe Flanges and Flanged Fittings.

WELDED OR THREADED ENDS

ASME B16.25: Buttwelding ends

ASME B16.25: Buttwelding ends ASMEB16.11: Forged fittings, socket-welding and threaded.

ASMEB16.11: Forged fittings, socket-welding and threaded. ASME B1.20.1: Pipe threads general purpose.

ASME B1.20.1: Pipe threads general purpose.

FACE TO FACE AND END TO END

ASME B 16.10: Face-to-Face and End-to-End Dimensions of Valves.

ASME B 16.10: Face-to-Face and End-to-End Dimensions of Valves.

Check Valves

Our Check Valves are reliable and efficient flow control devices designed to prevent backflow and protect against contamination and equipment damage.

Types:

Swing check / Dual plate / Tilting Disc / Piston check / Ball check / Single

Swing check / Dual plate / Tilting Disc / Piston check / Ball check / Single Disc / Axial check

Disc / Axial check

Construction:

Bolted bonnet / Pressure seal

Bolted bonnet / Pressure seal Wafer / Lug / Double flanged

Wafer / Lug / Double flanged

Optional features:

Position indicator

Position indicator Locking device

Locking device Emergency assisted valves.

Emergency assisted valves. Dumpered valves

Dumpered valves

Materials:

Our Check valves are supplied with all material types to fulfill all the different combinations of service fluid, design pressure, and temperature. Valves can be supplied either forged or cast based on customer specifications. The following materials are under the scope of our supply.

Carbon Steel valves

Carbon Steel valves Low-temperature carbon steel

Low-temperature carbon steel High-temperature alloy steel

High-temperature alloy steel Stainless Steel Valves

Stainless Steel Valves Super Austenitic Stainless Steel

Super Austenitic Stainless Steel Duplex Stainless Steel

Duplex Stainless Steel Super Duplex Stainless Steel

Super Duplex Stainless Steel Ni Alloy

Ni Alloy Titanium

Titanium Aluminum bronze

Aluminum bronze

Powerline can supply any of the materials mentioned above to fulfill any additional requirement included in customer specifications.

Pressure Safety Valves

Safety valves are a type of automatic valve designed to automatically open and discharge fluids when the pressure reaches the designated value, then automatically close again when the pressure falls below the designated value. They are used as a safety device to protect equipment, instrumentation, and piping from excessive pressure.

Our line-up of full-lift safety valves offers models suitable for steam, air water, and other non-hazardous fluids.

We are a specialist supplier of safety relief valves with a complete range of sizes ½ to 20″, rating until ANSI 2500, and all types of materials such as nodular, carbon steel, low-temperature carbon steel, stainless steel, Inconel, Duplex, Super Duplex, and special coating in ECTFE/ Halar. Our products comply with the Pressure Equipment Directives 2014/68/EU and ATEX 2014/34/EU, as well as with the regulations in force for each of the sectors and corresponding applications. They are designed and manufactured under strict quality control ISO 9001:2015.

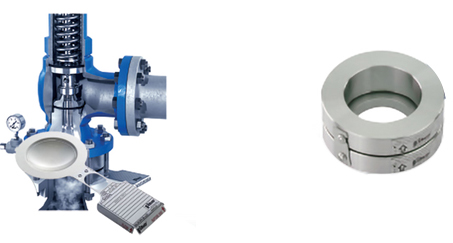

Control Valves

In need of high-quality control valves? we provide expert solutions for your project. Control valve with optional actuators, end connections, and materials.

We are supplying good quality control valves and steam conditioning equipment to facilitate the processing of industries that include Oil and Gas Exploration, Storage and Transmission, Refining and Petrochemicals, Fertilizers, Power, Pulp and Paper, Steel and Allied Industries, Chemical, and pharmaceutical industries.

We are supplying good quality control valves and steam conditioning equipment to facilitate the processing of industries that include Oil and Gas Exploration, Storage and Transmission, Refining and Petrochemicals, Fertilizers, Power, Pulp and Paper, Steel and Allied Industries, Chemical, and pharmaceutical industries.

Custom Made Engineered Valves

We offer a complete range of application-specific valves from premier legacy brands. Our highly engineered valves are known to be durable, long-lasting, and field-proven in the most severe conditions.

Our tailor-made valves are available in both forged and cast exotic materials, with short delivery times.

Pipe, Fittings and Flanges

We are supplying pipe, butt weld fittings, socket weld & threaded fittings, and flanges in a variety of types, sizes, schedules, and pressures and we can deliver orders timely to meet your project time requirements and offer expedited lead times for special or custom requests.

Our supplies include, but are not limited to, carbon steel, stainless steel, PVC S80, CPVC S80, and specialty alloy materials. Our highly trained staff will help you with your pipes, flanges, fittings, structural shapes, and related components.

Thermoplastic Valves

We have experience in the supply of industrial plastic valves, we offer solutions for your applications wherever you are.

We offer a combination of quality, safety, and product suitability for your applications and installations. Whatever your industry, from chemical to mining, from water processing to agriculture, we can offer more than just products - solutions to problems.

Thermoplastic Valves (Ball, Check & Butterfly Valves)

Actuators

We supply actuators that enable you to take control of your plant fluids with reliability and safety. Anytime, anywhere.

If you are working with fluids such as gas, oils, high-pressure air, and water need zero leaks and control in any situation.

We are laser-focused on supplying high-performance actuators, built with the technology for your needs in industrial, commercial, and residential applications. We offer actuators, actuated valves, and completely assembled kits to help you waste no more resources

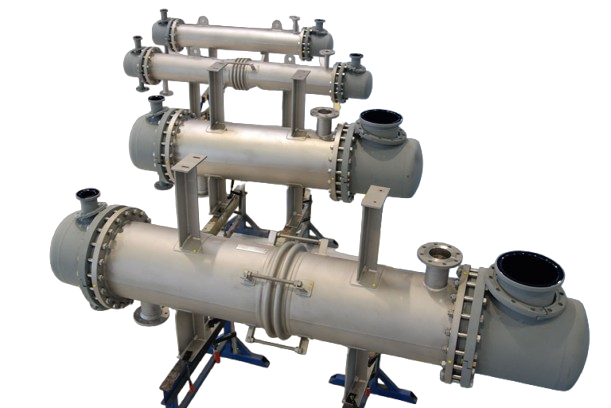

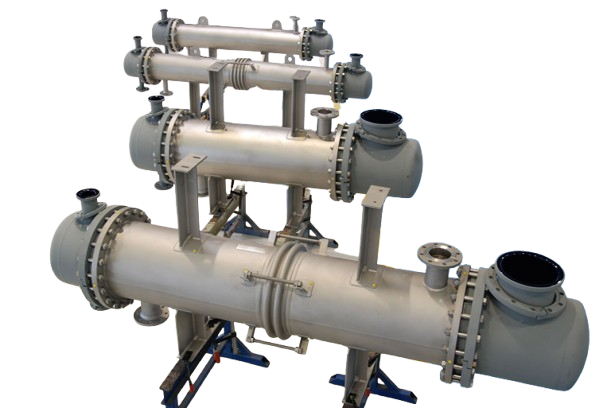

Heat Exchangers and Condensers

We, Powerline offer a full range of Heat exchangers and Condensers standardized product lines for an optimal price/quality ratio as well as customized designs for the most demanding duties in oil & gas, petrochemical, power generation, marine, refrigeration, and many other industries.

Cost-efficient and reliable solutions

Shell & Tube heat exchangers are the most common designs for many applications. We provide a wide variety of applications based on the most suitable design and materials to ensure a cost-efficient and reliable solution.

Heat Exchanger offers major advantages for applications where oil or air has to be cooled. The enlarged surface on the shell side compensates for the lower heat transfer value of such media. It is ideal for customers who require a reliable, low-maintenance, and high-quality heat exchanger that is also long-lasting and takes up minimum space. Due to its robust design, the heat exchangers have good resistance to vibrations and shock loads.

Knife Gate Valves

Powerline supplies a wide range of knife gate valves, penstocks/slide gates, dampers, and valves for hydraulic works used in various industrial segments, such as Water Treatment, Mining, Power Generation, Pulp and Paper, Food and Beverage, Petrochemical Industry, Steel Industry, Air Separation, dams, Reservoirs, and Hydro Solutions.

Features

Our knife gate valves provide total operational reliability:

Gland box packing and machined support

Gland box packing and machined support Easy maneuvering and low energy consumption

Easy maneuvering and low energy consumption Low maintenance through gate guidance via stable top works

Low maintenance through gate guidance via stable top works Unique seat design and seat material for high performance and low LCC

Unique seat design and seat material for high performance and low LCC No flow restriction fully open

No flow restriction fully open One piece casting body

One piece casting body Stainless steel gate

Stainless steel gate Robust gland box packing system

Robust gland box packing system

Applications

Our knife gate valve is designed and equipped to handle tough and abrasive shut-off applications involving slurries, powders, granular substances, pulp stock, paper, and recycled paper.

Mining and minerals processing

Mining and minerals processing Pulp and paper applications

Pulp and paper applications Water & wastewater

Water & wastewater Sand and gravel plants

Sand and gravel plants Tailing lines

Tailing lines Abrasive slurry materials

Abrasive slurry materials

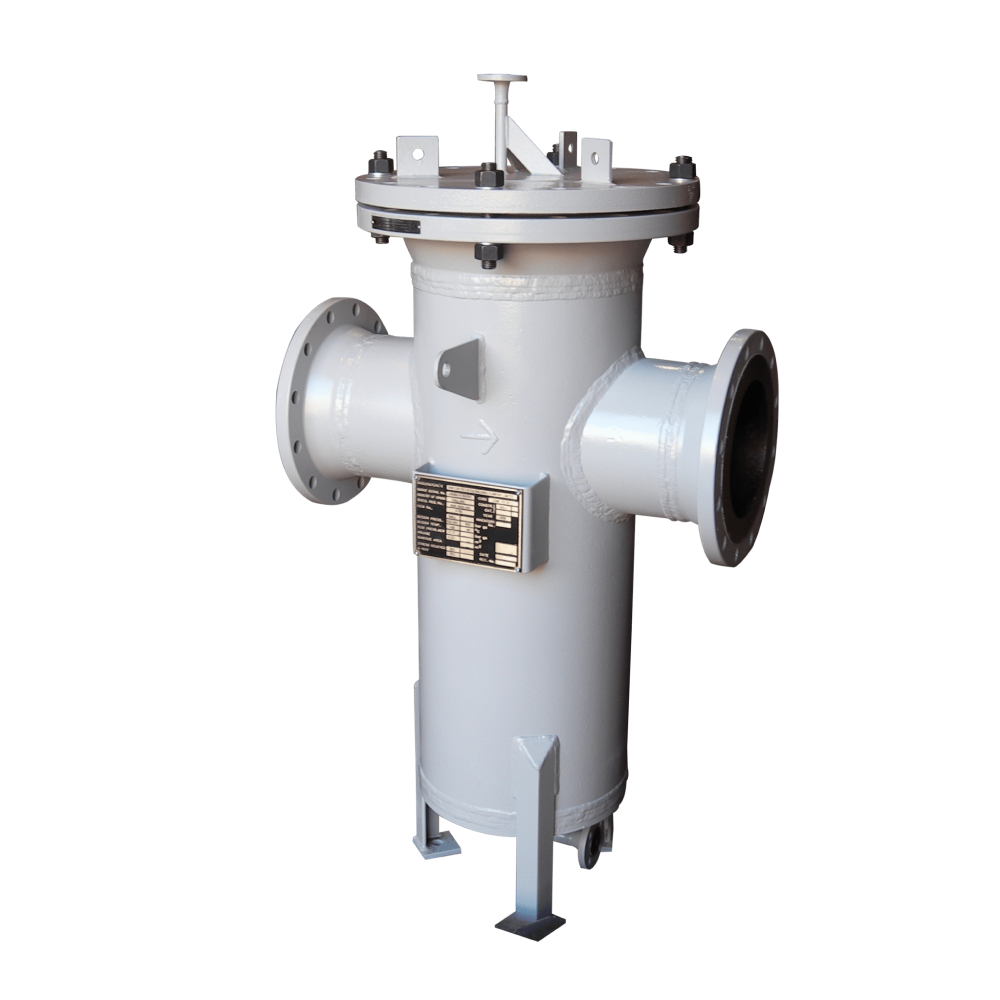

Strainers Filters Flame Arresters

We represent BARTON FIRTOP, a competitive Designer, Manufacturer and Supplier of:

1. Strainers

Low-Loss Strainers & Mono Inline Basket Strainers

Low-Loss Strainers & Mono Inline Basket Strainers Y-Type & T-Type Strainers

Y-Type & T-Type Strainers Duplex Strainers

Duplex Strainers

2. Filters

Cartridge Filters

Cartridge Filters Self-Cleaning Filters

Self-Cleaning Filters

3. Flame Arresters

We are experts in project design and project management, focused to achieve on-time delivery of strainer and filtration equipment to meet complex project specifications for materials, manufacture, NDE, documentation and Quality Control.

We manufacture strainers with 'lowest pressure drop in the world'. The size ranges from 0.5” NB (DN 15mm) up to 90” NB (DN 2200mm). Can make in any material including exotic materials (for severe applications).

Heat Exchangers & Condensers

We, Powerline offer a full range of Heat exchangers and Condensers standardized product lines for an optimal price/quality ratio as well as customized designs for the most demanding duties in oil & gas, petrochemical, power generation, marine, refrigeration, and many other industries.

Cost-efficient and reliable solutions

Shell & Tube heat exchangers are the most common designs for many applications. We provide a wide variety of applications based on the most suitable design and materials to ensure a cost-efficient and reliable solution.

Heat Exchanger offers major advantages for applications where oil or air has to be cooled. The enlarged surface on the shell side compensates for the lower heat transfer value of such media. It is ideal for customers who require a reliable, low-maintenance, and high-quality heat exchanger that is also long-lasting and takes up minimum space. Due to its robust design, the heat exchangers have good resistance to vibrations and shock loads.

Fike is a globally recognized supplier of products and services that protect people and critical assets from dangers such as fire, explosion, and over-pressurization.

Fike offers reliable rupture (bursting) discs for liquid or vapor applications in a wide range of sizes and materials.

Fike offers reliable rupture (bursting) discs for liquid or vapor applications in a wide range of sizes and materials. Sizes available from 1” to 56”

Sizes available from 1” to 56” We size a wide range of rotary lobe blowers and vacuum boosters into applications spanning several markets. Custom engineered blower package are available to meet the unique specifications of your application.

We size a wide range of rotary lobe blowers and vacuum boosters into applications spanning several markets. Custom engineered blower package are available to meet the unique specifications of your application. Up to 95% operating ratio available

Up to 95% operating ratio available Extrusion discs (suitable for extrusion processes) & Engineered discs for special applications also available.

Extrusion discs (suitable for extrusion processes) & Engineered discs for special applications also available.  Fike’s VALVEGUARD concept uses rupture discs to isolate your Pressure/Safety Relief Valves, protecting them from process media and downstream contaminants.

Fike’s VALVEGUARD concept uses rupture discs to isolate your Pressure/Safety Relief Valves, protecting them from process media and downstream contaminants. Fike ’s high quality vents are accepted globally as it can be installed and maintained easily. Fike manufactures rectangular & circular vents.

Fike ’s high quality vents are accepted globally as it can be installed and maintained easily. Fike manufactures rectangular & circular vents.

Croll Reynolds is an engineering firm specializing in the research, design, and manufacture of process vacuum systems, combination liquid ring/ejector systems, thermo compressors, vacuum chillers and pollution control systems.